How to Choose the Right Sound Deadening Material for Your Project

When embarking on a soundproofing project, selecting the right sound deadening material is crucial for achieving effective results. According to a report by the Acoustical Society of America, noise pollution increases by approximately 15% in urban areas, significantly affecting quality of life. Utilizing sound deadening materials not only enhances comfort in living and working spaces but can also contribute to property value, as properties with superior sound insulation report a 10-20% increase in market appeal.

When embarking on a soundproofing project, selecting the right sound deadening material is crucial for achieving effective results. According to a report by the Acoustical Society of America, noise pollution increases by approximately 15% in urban areas, significantly affecting quality of life. Utilizing sound deadening materials not only enhances comfort in living and working spaces but can also contribute to property value, as properties with superior sound insulation report a 10-20% increase in market appeal.

With a multitude of options available, including mass-loaded vinyl, foam panels, and acoustic curtains, it’s vital to consider factors such as the material’s density, installation convenience, and specific noise reduction capabilities. Understanding these aspects will empower homeowners and contractors alike to make informed decisions, ultimately optimizing their soundproofing efforts while ensuring a serene environment.

Understanding Your Noise Reduction Needs for Sound Deadening

When selecting sound deadening materials for your project, it's crucial to first understand your specific noise reduction needs. Different environments and activities produce varying levels of noise, and recognizing whether you require sound isolation, absorption, or damping can significantly influence your choice. For instance, if you're working in a residential area with noise complaints, you may prioritize sound isolation materials that prevent noise from traveling through walls or floors. Conversely, a recording studio might require materials that absorb sound to reduce echoes and improve audio clarity.

Additionally, consider the types of noise you are dealing with—impact noise, airborne noise, or both. Impact noise, often caused by footsteps or dropped objects, requires denser materials like rubber mats or specialized underlays, while airborne noise, originating from voices or music, can be effectively reduced with soft, porous materials such as acoustic foam or fiberglass panels. By assessing the noise characteristics of your environment and understanding the acoustic properties of different materials, you can make an informed decision that best meets your project's requirements.

Evaluating Different Types of Sound Deadening Materials

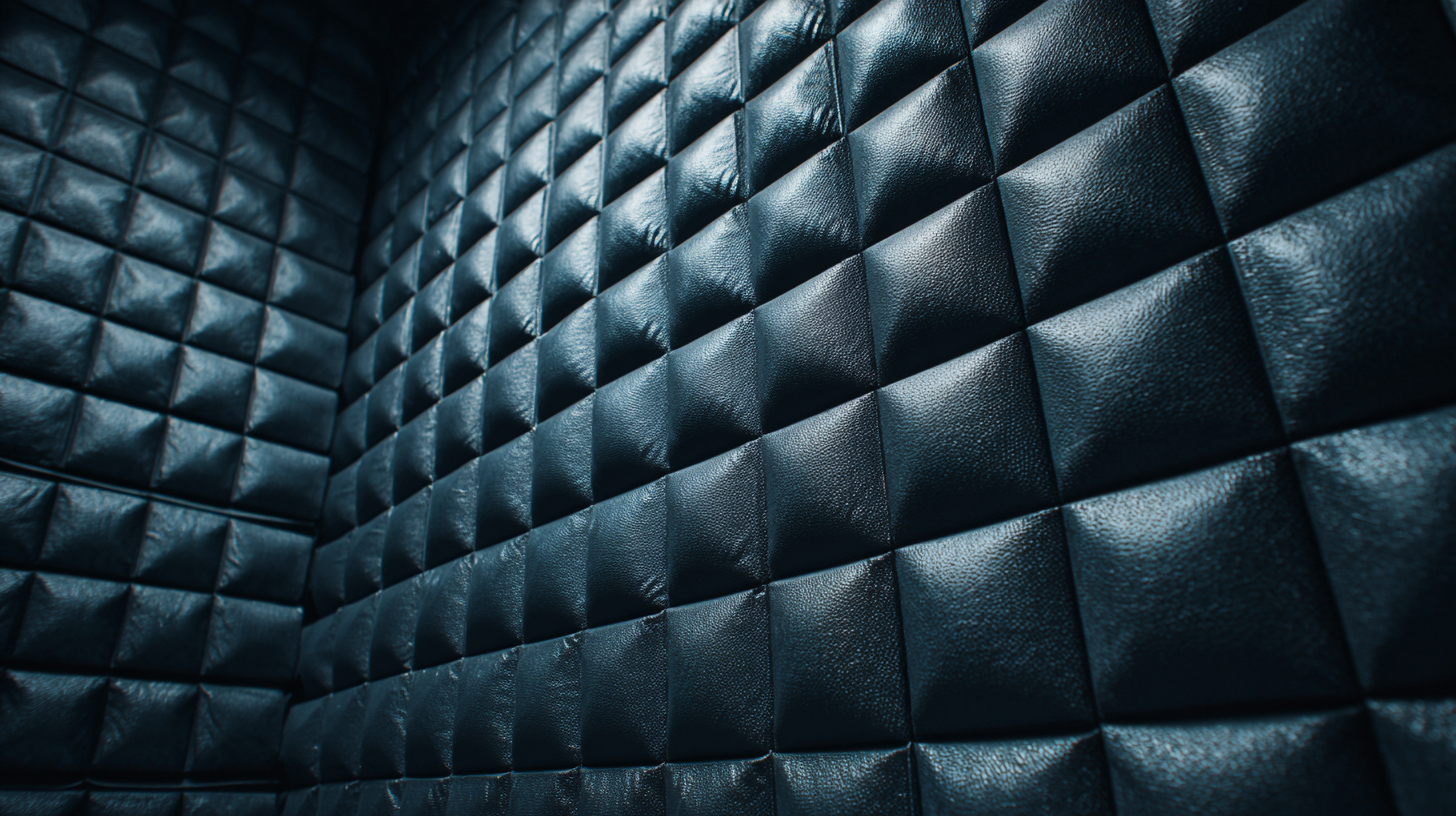

When evaluating different types of sound deadening materials, it's important to consider the specific needs of your project. Foam materials are popular choices for interior spaces, providing good sound absorption and easy installation. They work best in areas like studios or offices where reducing echo is essential. However, foam tends to be less effective at blocking low-frequency sounds, which may be a consideration if you’re dealing with loud machinery or bass-heavy audio.

On the other hand, mass-loaded vinyl (MLV) is highly effective for blocking sound transmission, making it ideal for walls, floors, and ceilings in more demanding environments. Its high density helps to prevent sound from passing through, making it suitable for applications like home theaters or music rooms. Another option is acoustic panels, which not only help with sound absorption but can also enhance the aesthetic appeal of a space. Each material serves a unique purpose, so understanding their properties and your specific soundproofing requirements will guide you in selecting the most appropriate sound deadening solution for your project.

How to Choose the Right Sound Deadening Material for Your Project - Evaluating Different Types of Sound Deadening Materials

| Material Type | Thickness (mm) | STC Rating | Cost per sq ft | Installation Difficulty |

|---|---|---|---|---|

| Foam Panels | 25 | 18 | $1.50 | Easy |

| Mass Loaded Vinyl (MLV) | 2 | 27 | $2.00 | Moderate |

| Acoustic Caulk | Unknown | 22 | $0.75 | Easy |

| Soundproofing Mats | 10 | 20 | $1.80 | Moderate |

| Resilient Channels | Unknown | 25 | $0.50 | Difficult |

Factors to Consider When Selecting Sound Insulation Materials

When selecting sound insulation materials for your project, several critical factors come into play. First, it’s essential to consider the material's Sound Transmission Class (STC) rating, which measures how well a building material reduces sound transmission. According to the Acoustical Society of America, materials with an STC rating above 50 are typically effective in blocking significant sound, which is crucial for residential or commercial applications.

Another important factor is the density of the material. Denser materials, like Mass Loaded Vinyl (MLV), can effectively dampen sound waves due to their ability to absorb and reflect sound. A study by the National Institute of Standards and Technology found that increasing the mass of sound insulation can significantly enhance its performance, with some materials demonstrating a 10 to 15 decibel improvement in sound reduction. Additionally, consider the frequency range of the sound you’re trying to block. Different materials perform better at isolating specific frequency bands, so a one-size-fits-all approach may not be suitable.

Lastly, installation ease and compatibility with existing structures should not be overlooked. Whether you're soundproofing a home theater or an office, ensuring that the chosen material can be seamlessly integrated will not only enhance the sound dampening effect but also maintain the overall aesthetic appeal of your space.

Sound Deadening Material Comparison

Application Techniques for Effective Sound Deadening Installation

When it comes to effective sound deadening installation, applying the right techniques can significantly enhance the performance of the materials you choose. According to a report by the Acoustical Society of America, soundproofing materials can reduce noise levels by up to 20 decibels when installed correctly. A crucial first step is ensuring that surfaces are clean and dry before application. This not only allows for better adhesion but also maximizes the material's efficacy in blocking unwanted noise.

Another important technique is to use a combination of soundproofing materials to tackle different types of noise. For example, mass-loaded vinyl (MLV) is highly effective against airborne noise, while acoustic foam excels in controlling reverberation. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that layering materials can create a more comprehensive barrier, yielding substantial improvements—often reducing sound transmission by as much as 50% in certain applications.

Properly sealing gaps and joints with acoustic caulk can also ensure that sound cannot slip through, further enhancing the overall effectiveness of your sound deadening project.

Budgeting for Quality Sound Deadening Solutions in Your Project

When it comes to sound deadening materials for your project, establishing a budget for quality solutions is crucial. According to a recent report by the National Institute of Standards and Technology, inadequate sound insulation can affect not only comfort but also productivity, especially in shared spaces. Investing in superior materials can significantly improve acoustic performance, with effective solutions ranging from $1.50 to $4.00 per square foot, depending on the type of material selected.

When it comes to sound deadening materials for your project, establishing a budget for quality solutions is crucial. According to a recent report by the National Institute of Standards and Technology, inadequate sound insulation can affect not only comfort but also productivity, especially in shared spaces. Investing in superior materials can significantly improve acoustic performance, with effective solutions ranging from $1.50 to $4.00 per square foot, depending on the type of material selected.

It's essential to consider both short-term costs and long-term benefits when budgeting for sound deadening solutions. Research by the Acoustical Society of America indicates that while initial investments in quality materials may seem higher, they can lead to reduced noise complaints and improved user satisfaction, ultimately saving costs related to renovations and modifications. By allocating a reasonable portion of your project budget to high-quality sound deadening products, you set the foundation for a more tranquil and productive environment.