Trusted by 100,000+ organizations across the globe

Personal protective equipment (PPE) detection is a necessary safety measure, as it checks workers’ attire to protect them from occupational safety risks. Supervisors and site managers understand how PPE detection is crucial to industries with higher human risk. However, checking every worker for PPE compliance can be a significant challenge.

According to OSHA, PPE can prevent 37.6% of workplace injuries and diseases. Workplace injuries and accidents can cost businesses significantly financially and in time, making the need for more efficient PPE detection more apparent.

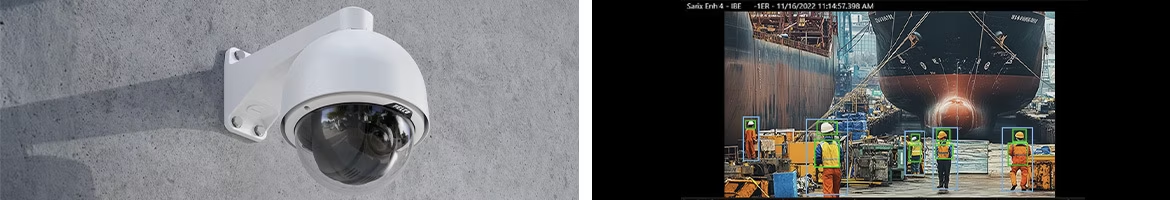

PPE detection technology consists of camera devices that provide real-time visual data and AI-assisted analytics to help improve safety, mainly by identifying improper PPE use and prospective environmental hazards. This guide will explore PPE detection, how the security technology works, its applications and what to consider when choosing a system for your organization.

What is PPE detection?

PPE detection technology uses visual data to identify appropriate safety attire for individuals. Organizations worldwide have adopted this practice to improve worker safety and help comply with any safety regulations.

Examples of PPE include:

- Helmets: hard hats to protect heads

- Safety glasses: reinforced glasses to protect the eyes

- Gloves: durable material to help protect hands

- Shoes: reinforced footwear to minimize the risk of foot injury

- Earplugs: protecting hearing in louder environments

- Respirators: reduce the risk of inhaling matter in hazardous atmospheres

- Coveralls: a full-body suit to protect the user from harmful substances

- Vests: brightly colored to enhance visibility in lively or low-light environments

If you’re a manager or supervisor, PPE monitoring can help confirm your team has the appropriate attire on work sites or in any environment that poses risks to safety. The system can help detect when PPE is missing and notify the relevant party to take immediate action and minimize inspection errors.

Enhance worker safety with PPE detection

- Detect PPE violations in real time

- Prevent injuries and comply with regulations

- Removes the need for manual inspections

- Enabled through Pelco Elevate in seconds

How does AI PPE detection work?

PPE detection through manual and automated methods presents challenges, leaving margins for error in many complex working environments. Human inspections can sometimes overlook a PPE violation, whereas cameras occasionally struggle to register specific equipment under poor conditions.

Advancements in AI can channel improvements in conducting inspections, facilitating a more efficient way to perform automated PPE detection using computer vision. AI-assisted PPE monitoring technology combines adaptive algorithms, improved visual data analysis and real-time communication to identify issues and reduce risks.

Examples include using weather-resistant hardware and machine learning algorithms to actively detect essential PPE items such as vests, helmets and other protective gear. If the device detects an anomaly, the system can notify the supervisor or manager on duty, prompting swifter response times — some configurations can even include notifying the worker directly.

Here’s a phased breakdown of how AI PPE detection using computer vision works:

- Visual detection: Computer vision identifies workers in the line of sight wearing PPE, such as hard hats, safety goggles and high-visibility vests.

- Image classifying: AI-assisted analysis categorizes visual data based on PPE compliance and non-compliance model training.

- Real-time notification: The system immediately alerts supervisors or workers in non-compliance cases.

- Advanced analysis: The network uses deep learning algorithms to interpret visual data and improve detection accuracy.

The machine learning models behind the advanced analysis can learn to detect essential PPE by identifying color, shape and other key markers, improving measurement capabilities for specific items and accurate detection. The system analyzes thousands of visual inputs to help recognize appropriate PPE use, supporting safer working conditions and evolving depending on revised guidelines or new regulations.

Benefits of PPE detection

Workplace safety challenges show how AI-assisted PPE monitoring can support a safer and more efficient environment, helping organizations prevent incidents and stay compliant with evolving safety standards. Below are some of the leading reasons to support the technology’s implementation.

24⁄7 visibility

AI PPE detection technology operates around the clock to help enhance workplace safety. With low-light capabilities and infrared technology, the systems analyze real-time visual data day and night, checking for PPE compliance and reducing the need for constant manual inspections.

Mitigate accident risk

Continuous visibility supports PPE monitoring technology in reducing the risk of accidents. By identifying improper PPE use in real-time, these systems can help reduce incident risk and notify teams to take prompt action.

Reduced human error

Manual PPE inspections by humans can strain resources and increase the margin of error when enforcing safety attire policies. Systems support supervisors by helping detect PPE use automatically, allowing them to focus on the site’s broader safety oversight.

Increased safety standards

While improved safety practices across the workplace lead to fewer incidents, operational tasks can change quickly, potentially meaning new safety considerations. AI-assisted camera systems will adapt to new and updated safety protocols, helping identify risks in dynamic work environments.

Regulatory compliance

Regulatory compliance in many industries requiring PPE can be complex, with many guidelines to follow for worker safety, as outlined in the National Institute of Standards and Technology. AI PPE detection systems can support compliance by aligning with key safety standards and helping reduce the chance of oversight.

Cost savings

Automated systems can reduce manual PPE inspection time and labor costs. By operating continuously, there is a reduced requirement for human oversight. Additionally, AI algorithms can adapt to evolving safety standards over time, helping maintain effectiveness without ongoing support costs.

Data-driven decision making

AI PPE detection data can offer insights into operational gaps, safety risks and areas for improvement. The data collected through AI-assisted analysis can help prepare future strategies and optimize safety measures and operational planning.

Industry applications of PPE detection

AI PPE detection supports safer operations across a range of industries with higher-risk operations. Below are examples of how this technology can help you reduce risk and improve workplace efficiency.

Construction

Construction workers are three times more likely to have a workplace accident if they do not use PPE. Site operations often involve working from heights and surfaces with slip or trip hazards. Hard hats and high-visibility vests are essential for worker safety, where head and hand injuries are more common.

Real-time PPE detection can help forepersons and site managers identify missing or improperly used PPE, reducing worker safety risks from equipment and environmental hazards. The detection technology, combined with AI analytics, helps promote a safer building site and more efficient operation.

Oil and gas

The oil and gas industry carries significant risk, mainly due to the operational hazards of drills, working at heights and potential exposure to harmful particulate matter. According to OSHA, many workplace incidents result from improper use or insufficient PPE, such as falls from insecure personal fall arrest systems (PFAS).

Oil and gas security systems with PPE detection technology use visual analytics to help identify safety risks related to personnel, including not wearing high-visibility vests in low-light conditions, and the unique work environments in the industry. Some systems can integrate air quality sensors and assist in identifying missing or improperly worn fall protection gear.

Manufacturing

Manufacturing has had a considerable number of workplace accidents. Due to its complex operations, the industry is prone to safety risks. Factories and warehouses’ leading concerns range from heavy equipment misuse to theft.

PPE detection technology can benefit humans and equipment alike. Systems can help accurately identify safety violations, such as workers not wearing PPE like helmets, gloves and reinforced footwear, provide predictive maintenance for machine failure and deliver real-time, AI-assisted insights to develop more efficient manufacturing logistics.

Healthcare

Hospitals, labs and medical clinics can be particularly hazardous due to the number of chemicals, biological agents and contaminated surfaces involved in the industry. Most healthcare facilities require gloves, masks, gowns, respirators and even hazmat suits for hazardous scenarios.

PPE detection helps verify that individuals entering the facility have the required protective gear. The real-time visual data can help notify personnel of any possible physical security breach, including PPE violations, hazardous surfaces or unauthorized access.

Public safety

In public-facing operations where safety is critical, PPE detection can support faster incident awareness and improved protection for teams and communities. AI-assisted analytics can support safety operations in public transit, crowd management and emergency response.

AI systems can analyze visual data to identify peak crowd times, helping agencies adjust staffing and response protocols. These insights can support efficient staff rotas, proactive safety measures and quicker incident response. PPE detection devices can even provide data that helps plan for a more efficient urban space.

Mining

Thousands of injuries and accidents occur yearly in mining due to slips, falls and mechanical errors. Because the industry involves confined spaces, PPE detection can assist with real-time visual analysis of the operation, which can be crucial to personnel safety.

Implementing mining cameras can reduce costs and errors associated with manual inspection. They can also detect hazardous materials, objects and markers for equipment failure and PPE. Should a worker enter a mine without appropriate PPE, alerts from the PPE detection software will notify site managers so corrective action can be taken.

Hospitality

Large-scale food and beverage operations carry safety risks such as exposure to hot surfaces, sharp tools and heavy equipment. Many industrial-grade kitchens feature heavy machinery and degradable products, where incorrect procedures can pose hazards to workers and the general public.

PPE detection technology helps confirm that food and beverage preparation procedures are correct and that staff wear the necessary equipment to protect themselves and the product quality, such as gloves and hairnets. AI-assisted analytics can further enhance the operation as production scales and regulations change.

As industries evolve, PPE detection continues to offer value across new environments. Its visual and AI-enabled capabilities can support safer operations wherever people and risks intersect and are not limited to the above industries.

Six considerations for choosing and installing PPE detection cameras

This guide has outlined how PPE detection can provide safety and operational improvements for organizations across various industries. If your business plans to integrate a system, the six considerations below can help guide your decision when choosing and implementing PPE detection cameras.

1. Installation

An ideal installation is key to ensuring that the system captures accurate and usable data. When setting up, review environmental factors such as poor lighting, object obstructions and placement angles to get the most coverage and accurate results.

Site assessments can help determine optimal PPE detection camera choices and whether the system requires professional installation or in-house configuration.

2. Reliability

Implementing PPE detection cameras requires proven reliability in your operational area, as different systems can perform better depending on environmental factors and industry. Low light, motion blur and adverse weather can impact detection — understanding their accuracy statistics and industry case study results is a consideration in your decision.

3. Integration with existing systems

Many organizations in different industries run legacy systems, potentially posing integration challenges. Businesses may have varying video management systems (VMS) in place. However, consultations with PPE detection product experts can help you understand how to integrate devices with your existing business security system, including any required middleware or API compatibility.

4. Compliance

While PPE detection cameras can help identify issues and assist in complying with safety regulations, considerations also include personal data compliance laws. Look for systems with built-in features that support responsible visual data use, such as redaction capabilities, and compliance with data protection regulations like GDPR.

5. Cost efficiency

Cost is one of the primary considerations when choosing and implementing PPE detection, as it can include more than a single upfront cost. Commercial cameras can have varying expenses, including operational licenses, software updates, data storage and ongoing support. Consider whether a subscription or one-time purchase model best fits your budget.

6. Scalability

If your organization plans to grow or expand to new sites, ensure the system can scale to meet operational needs. In these cases, cloud-based or modular systems that support multi-site deployments could offer the most flexibility.

AI-assisted systems that can be updated or configured for new PPE types and regulations will offer long-term value as your business evolves. This flexibility can be significant for organizations managing multiple facilities with varying safety requirements.

Enhance worker safety with Pelco PPE detection

Since 1957, Pelco, a global leader in security hardware, has continued to engineer devices that set a new standard for security, safety and operational efficiency. Its range of specialized cameras and sensors is purpose-built to perform in harsh and hazardous environments, challenging weather conditions and where long-range detection is required.

Pelco security cameras and devices are built on an open platform, meaning they are interoperable and work with any ONVIF-conformant VMS. This provides effortless integration for new installations or with your existing security systems, enabling you to leverage your existing investments and save time and money.

Through continuous development in advanced video analytics and AI-powered cloud capabilities, Pelco is dedicated to perpetually enhancing the functionality and intelligence of its products. These ongoing advancements provide organizations with deeper insights and streamlined operations, helping them become more knowledgeable, efficient and safer over time.

PPE detection analytics with Elevate

Elevate is Pelco’s direct camera-to-cloud technology that combines edge and cloud AI. It maximizes the potential of your Pelco cameras without requiring additional hardware, providing exceptional performance and detection accuracy to optimize efficiency.

As part of the offering, Elevate provides real-time PPE detection analytics. This feature alerts operators when PPE rule violations are detected, such as missing or incorrect PPE usage, including high-visibility jackets and hard hats. As a result, Elevate’s PPE detection analytics:

- Promotes safe working conditions: Detect PPE violations in real time and proactively act to prevent potential worker injuries and comply with safety regulations.

- Improves safety efficiencies: Automated PPE monitoring removes the need for manual inspections, making it easier to track PPE usage across large or remote sites.

- Deploys and scales easily: PPE analytics can be enabled through Elevate on select Pelco cameras in seconds.

Discover how you can extract the maximum potential of your Pelco cameras and enhance workplace safety with PPE detection analytics from Elevate.

Personal protective equipment detection technology that fits your operations

This guide, along with the above mentioned factors, can help you understand and implement personal protective equipment detection technology that fits your operations, supports compliance and enhances workplace safety. As PPE detection continues to evolve, future innovations may offer even more advanced ways to safeguard your workforce.